Self Propelled

Bed Quickly and Efficiently The Self Propelled SideShooter will decrease time needed to bed freestalls while reducing amount of material wasted from improper placement.

Bed Quickly and Efficiently The Self Propelled SideShooter will decrease time needed to bed freestalls while reducing amount of material wasted from improper placement.

Independent Conveyor Speeds The operator can independently control each conveyor speed (main conveyor & cross conveyor) to accommodate many different bedding types and moisture content in the bedding. The conveyors can be adjust quickly and easily with the turn of a dial from inside the cab.

Excellent Visibility The positioning of the cab allows the operator to watch the cross conveyor, the main conveyor, and the material being spread.

Rugged Cab Construction The cab features military grade components for long service life. With no controls on the floor to be damaged by the corrosive manure and sand. The rugged cab is easily cleaned.

Cross Conveyor The cross conveyor uses an aggressive high speed track, this allows the conveyor to place bedding 3 to 25 feet. Also the track is seamless and fiberglass reinforced with positive drive cogs to provide rugged durability without slipping under load.

Maneuverability Turning in cross alleys and around tight barns is effortless with the tight turning circle and the two steering modes. The operator can select from two wheel or four wheel steering.

Hydrostatic Drive The operator has precise control over ground speed using a hydrostatic drive. In addition the hydrostatic drive allows for varied ground speed while maintaining engine rpm to maintain material flow ensuring each free stall is full of bedding.

Main Conveyor The main conveyor uses a heavy duty pintle chain and drive sprockets for long service life and low maintenance.

Bed Head to Head Stalls The high speed oscillating cross conveyor has the ability to angle upward and bed head to head free stalls with a single pass.

Low Maintenance The daily routine maintenance is as simple as checking fluids, walk around inspection and greasing bearings.

| Spec | M3600 | M3620 |

|---|---|---|

| Hopper Capacity Heaped | 15 cu. yd. | 20 cu. yd. |

| Operating Weight Empty | 18,500 lb. | 21,000 lb. |

| Operating Weight Loaded | 45,000 lb. | 65,000 lb. |

| Turning Circle | 7 ft. | 12 ft. |

| Wheelbase | 119 in. | 167 in. |

| Overall Length | 267 in. | 324 in. |

| Overall Height | 100 in. | 101 in. |

| Overall Width | 98 in. | |

| Engine | 160 hp | |

| Fuel Capacity | 60 Gallons | |

| Hydraulic Fluid Capacity | 25 Gallons | |

| Standard Tire Size | 385/65 R22.5445/65 R22.5 | |

| Parking Brake | Spring Applied Wet Disc | |

| Transmission | Hydrostatic | |

| Transfer Case | 2 Speed w/ High Range Lock Out | |

| Low Range Speed | 9 mph | |

| High Range Speed | 20 mph | |

| Discharge Distance | 3 ft. – 25 ft. | |

| Cab | Heat Standard / AC Optional |

Manure Vacuums

Simple Manure Management, Simple Barn Design Barns no longer need to have an integrated manure handling system during construction. The Manure Vacuum replaces the need for pumps, augers, and concrete channels to transport manure from the barn to the storage lagoon or process facility.

Simple Manure Management, Simple Barn Design Barns no longer need to have an integrated manure handling system during construction. The Manure Vacuum replaces the need for pumps, augers, and concrete channels to transport manure from the barn to the storage lagoon or process facility.

Reduce Time Spent Cleaning Alleyways The Manure Vacuum cleans the alley in one pass. Allowing more time to properly fill and groom free-stall bedding. In addition minimized time in the alleyway means reduced wear and tear on the equipment.

Rugged Durability The manure vacuum is manufactured from the highest quality of materials and components.

Reduce Expansion Cost With the manure vacuum, when a dairy expands their facilities there is no additional equipment to buy. The investment in the manure handling has already been made with a manure vacuum.

Flexible Farm Design With the ever changing regulations and restrictions manure systems are forced to change. The manure vacuum adapts to manure system changes.

Remote Manure Processing The location of a manure processing facilities is not limited to the ability to transfer the manure. The manure vacuum allows the transport of manure easily and reliably to anywhere on the dairy or even near by.

Adjustable Down Pressure The scraper head has adjustable down pressure. This allows the scraper to peel up and vacuum dry pasty sand laden manure.

Collection Wings and Curb Skis The collection wings also have adjustable pressures that float the skis along the curb allowing the operator to focus on maneuvering the machine and not the scraper head.

Cleaner Barnyards The manure vacuum scraper cleans the alley ahead of the tires keeping the barnyards and roads cleaner.

Clean Manure Along Curbs Unlike pull type vacuums and automatic alley scrapers the manure vacuum uses its curb skis to slide along alleyway curbs removing bacteria infested manure. This stops the bacteria from growing and the cows from tracking this manure into the free-stalls.

Vacuum Blower

Instant Suction The large vacuum blower allows the operator to have instant suction at the scraper head without waiting to build vacuum pressure on the tank.

Sand Laden Manure The powerful vacuum blower sucks up thick and heavy sand laden manure from dry cow and heifer barns.

Proven Reliability The domestic made vacuum blower is proven in many demanding and abusive industries such as oil fields, hydro digging, sewer cleaning trucks, and milking parlors.

Unloading System

Patented Unloading System A full length auger in the bottom of the tank allows for quick and easy unloading of all types of manure from sloppy wet manure to dry pasty sand laden manure.

Gate Valve The powerful vacuum blower sucks up thick and heavy sand laden manure from dry cow and heifer barns.

Proven Reliability The domestic made vacuum blower is proven in many demanding and abusive industries such as oil fields, hydro digging, sewer cleaning trucks, and milking parlors.

Gate Valve The gate valve controls the rate of unloading for specific applications, like discharging into a sand settling lane, mechanical sand separator, or manure digester.

Quick Unloading Unloads 3000 gallons in approximately 50 seconds.

| Specs | V 2510 | V 3410 | V 4500 |

|---|---|---|---|

| Tank Capacity | 2,200 gal. | 3,000 gal. | 4,300 gal. |

| Operating Weight Empty | 21,820 lb. | 23,160 lb. | 25,820 lb. |

| Operating Weight Loaded | 41,500 lb. | 50,000 lb. | 65,000 lb. |

| Turning Circle | 7 ft | 12 ft | 14 ft |

| Wheelbase | 95.5 in. | 138 in. | 158 in. |

| Overall Length | 20 ft. 5 in. | 23 ft. 10 in. | 25 ft. 1 in. |

| Overall Height | 10 ft. 1 in. | 10 ft. 1 in. | 11 ft. 1 in. |

| Overall Width | 8 ft. 1 in. | 8 ft. 1 in. | 8 ft. 2 in. |

| Scraping Width | |||

| Engine | 220 hp – 240 hp | ||

| Fuel Capacity | 60 Gallons | ||

| Hydraulic Fluid Capacity | 25 Gallons | ||

| Standard Tire Size | 425/65 R22.5 | ||

| Parking Brake | Spring Applied Wet Disc | ||

| Transmission | Hydrostatic | ||

| Transfer Case | 2 Speed w/ High Range Lock Out | ||

| Low Range Speed | 10 mph | ||

| High Range Speed | 20 mph | ||

| Vacuum Blower | 6in Lobe blower | ||

| Auxiliary Suction | 15′ Long 3″ Dia. Suction Hose | ||

| Spreading Option | Front Mount Side Discharge | ||

| Cab | Heat Standard / AC Optional |

Manure Scrapers

Mensch manure scrapers are used to scrape away manure quickly and easily. Getting right down to the ground the rubber edge cleans in as little as one pass. Made of durable industrial tires and attached to a sturdy 3 1/2 x 3 1/2 x 1/4 wall structural tubing frame, are scrapers are made to last. Rubber scrapers have many advantages over traditional steel blades.

M500 3-Point Manure Scraper

M600 Bucket Mount Manure Scraper

M700 Quick Tach Manure Scraper

M100 Rubber Replacement

| Width | 3 Point | Bucket | Quick Tach | Rubber | Base |

|---|---|---|---|---|---|

| 5′-5′ 11″ | M500-5 | M600-5 | M700-5 | M100-5 | M150-5 |

| 6′-6′ 11″ | M500-6 | M600-6 | M700-6 | M100-6 | M150-6 |

| 7′-7′ 11″ | M500-7 | M600-7 | M700-7 | M100-7 | M150-7 |

| 8′-8′ 11″ | M500-8 | M600-8 | M700-8 | M100-8 | M150-8 |

| 9′-9′ 11″ | M500-9 | M600-9 | M700-9 | M100-9 | M150-9 |

| 10′-10′ 11″ | M500-10 | M600-10 | M700-10 | M100-10 | M150-10 |

| 11′-11′ 11″ | M500-11 | M600-11 | M700-11 | M100-11 | M150-11 |

| 12′-12′ 11″ | – | – | M700-12 | M100-12 | M150-12 |

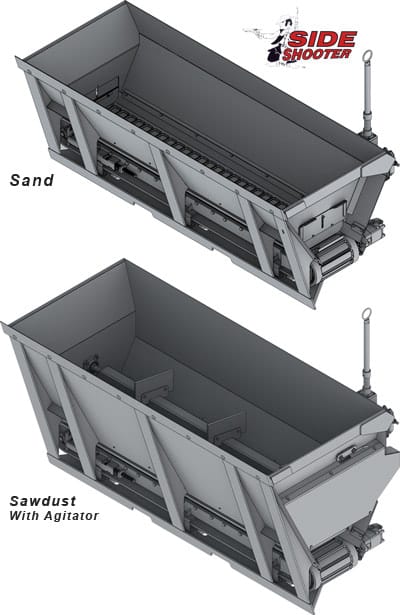

Side Shooter Buckets

Bucket Side-Shooters are designed to spread sand or sawdust into free stall barns, back fill, and can be used in many other applications. The bucket contains a positive drive conveyor that dispenses material from either side. From silage to stone the Mensch Side-Shooter shoots it all.

Bucket Side-Shooters are designed to spread sand or sawdust into free stall barns, back fill, and can be used in many other applications. The bucket contains a positive drive conveyor that dispenses material from either side. From silage to stone the Mensch Side-Shooter shoots it all.

- Positive drive conveyor system

- Durable endless loop track

- Dispenses contents from either side

- Optional agitator to prevent bridging of material

- Track speed varies with engine RPM and is controlled with auxiliary valve control of loader

- Flow is controlled by adjusting shoot door

- 5/8″ thick abrasive resistant steel bogie wheels

- Replaceable bolt on cutting edge

- Easy conveyor bearing grease access

| Model | Width | Type | Capacity | Weight | Req. Hyd. Flow min. |

|---|---|---|---|---|---|

| M1000 | 5 ft. | Sawdust | 1 yd. | 1,050 lb. | 10 gpm. |

| M1050 | 5 ft. | Sand | 0.5 yd. | 800 lb. | 10 gpm. |

| M1100 | 6 ft. | Sawdust | 1.33 yd. | 1,180 lb. | 11 gpm. |

| M1150 | 6 ft. | Sand | 0.66 yd. | 950 lb. | 13 gpm. |

| M2100 | 7 ft. | Sawdust | 1.5 yd. | 1,350 lb. | 11 gpm. |

| M1450 | 7 ft. | Sawdust | 2 yd. | 1,600 lb. | 11 gpm. |

| M2150 | 7 ft. | Sand | 1 yd. | 1,200 lb. | 14 gpm. |

| M2150-1 | 7 ft. | Sand | 1.75 yd. | 1,400 lb. | 15 gpm. |

| M2150-2 | 8 ft. | Sand | 2 yd. | 2,675 lb. | 15 gpm. |

| M1300 | 8 ft. | Sand | 3 yd. | 2,875 lb. | 15 gpm. |

| M1400 | 8 ft. | Sand | 4 yd. | 3,250 lb. | 15 gpm. |

Side Shooter Trailers

Trailer Side-Shooters are used to spread sand or sawdust in many applications including free stall barns. The trailer side-shooter uses a main conveyor to transfer the material to a cross conveyor that dispenses the material 3ft to 25ft.

| Model 3350 | Model 3355 | Model 3380 | Model 3390 | Model 3385 |

|---|---|---|---|---|

| Material: Sand | Material: Sand / Sawdust | Material: Sawdust | Material: Sand / Sawdust | Material: Sand |

| Struck: 7 yrd. / 5.3 m. | Struck: 8.5 yrd. / 6.5 m. | Struck: 11.5 yrd. / 8.8 m. | Struck: 11.5 yrd. / 8.8 m. | Struck: 13 yrd. / 10 m. |

| Heaped: 10 yrd. / 7.7 m. | Heaped: 11 yrd. / 8.4 m. | Heaped: 15 yrd. / 11.5 m. | Heaped: 15 yrd. / 11.5 m. | Heaped: 17 yrd. / 13 m. |

| Length: 208 in. / 529 cm. | Length: 208 in. / 529 cm. | Length: 256 in. / 650 cm. | Length: 256 in. / 650 cm. | Length: 256 in. / 650 cm. |

| Width: 84 in. / 214 cm. | Width: 87 in. / 221 cm. | Width: 90 in. / 229 cm. | Width: 90 in. / 229 cm. | Width: 90 in. / 229 cm. |

| Height: 90 in. / 229 cm. | Height: 99 in. / 252 cm. | Height: 99 in. / 252 cm. | Height: 99 in. / 252 cm. | Height: 100 in. / 254 cm. |

| Tank Length: 144 in. / 366 cm. | Tank Length: 144 in. / 366 cm. | Tank Length: 192 in. / 489 cm. | Tank Length: 192 in. / 489 cm. | Tank Length: 192 in. / 489 cm. |

| Side Angle: 54 de. | Side Angle: 68 de. | Side Angle: 68 de. | Side Angle: 68 de. | Side Angle: 58 de. |

| Chain Width: 30 in. / 76 cm. | Chain Width: 36 in. / 92 cm. | Chain Width: 36 in. / 92 cm. | Chain Width: 36 in. / 92 cm. | Chain Width: 30 in. / 76 cm. |

| Empty Weight: 8,075 lb. / 3,665 kg. | Empty Weight: 8,450 lb. / 3,835 kg. | Empty Weight: 9,080 lb. / 4,120 kg. | Empty Weight: 11,400 lb. / 5,170 kg. | Empty Weight: 11,400 lb. / 5,170 kg. |

Fluffers

Fluffers are used to aerate bedding speeding up its bacterial breakdown. They also level bedding, making it more comfortable and safer for cows.

M-950 Manual Fluffer w/ Tines

- Swing Beam 180 deg and slide tine mounting tube end for end for RH & LH operation

- Tine mounting tube is adjustable from 6.5 to 10 foot

- Roll bucket cylinders forward to level bedding, backwards to penetrate deeper

M-975 Hydraulic Fluffer w/ Tines

- Hydraulic rotating beam

- Tine mounting tube is adjustable from 6.8 to 10 foot

- Roll bucket cylinders forward to level bedding, backwards to penetrate deeper

M-960 Manual Fluffer w/ Spikes

- Low profile

- Front plate for leveling bedding

- Adjustable length for spike arm

M-980 Hydraulic Fluffer w/ Spikes

- Hydraulic rotating beam

- Low profile

- Adjustable length for spike arm

Feed Alley Scrapers

The feed alley scrapers are used to keep the feed close to cows. This makes cows more inquisitive encouraging them to get up and feed more.

- Blade scrapes clear of tire track so you won’t run over feed.

Rubber blades have many advantages over traditional steel blades:

- Outlast steel blades

- Takes vibration out

- Gentle on concrete

- Rubber blade does not rust

Stationary Blades

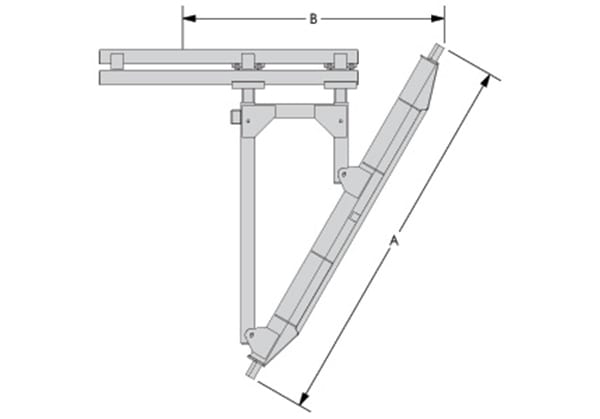

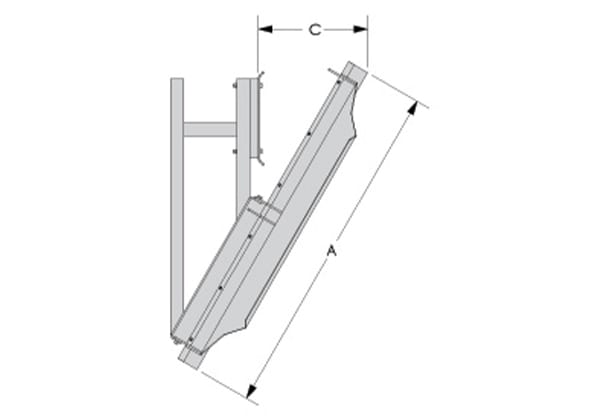

| Stationary Blades | M910 | M905 |

|---|---|---|

| Attachment Type | Universal | Bucket |

| Blade Width (A) | 95 in (241 cm) | 78 in (198 cm) |

| Blade From Center (B) | 65 in (165 cm) | |

| Blade From Bucket Edge (C) | 25 in (64 cm) |

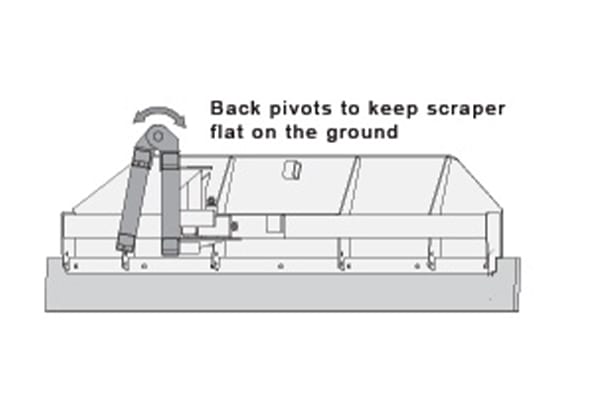

Rotating Blade

| Rotating Blade | M915 | M935 |

|---|---|---|

| Attachment Type | Universal | Universal |

| Blade Width (A) | 95 in (241 cm) | 95 in (241 cm) |

| Blade Width from Center (B) | 52 in (132 cm) | 52 in (132 cm) |

| Rotate Type | Hydraulic | Manual |

| Back Pivot | Optional |

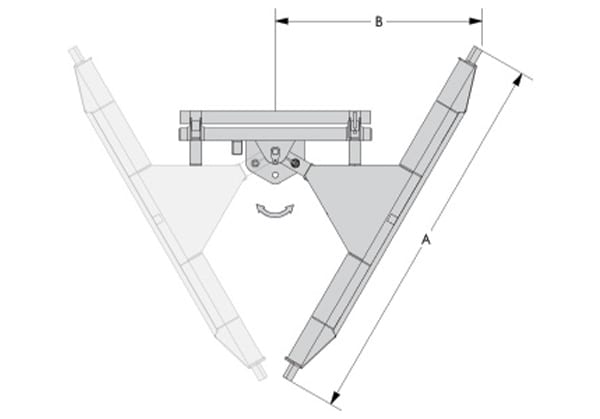

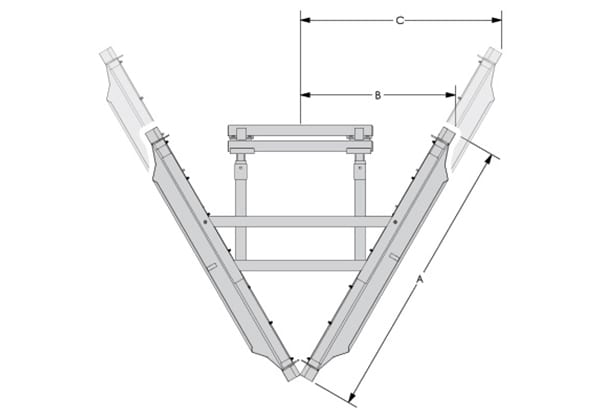

V Blade

| V Blade | M920 | M900 |

|---|---|---|

| Attachment Type | Universal | Bucket |

| Blade Width (A) | 95 in (241 cm) | |

| Blade Ahead (B) | 50 in (127 cm) | |

| Blade Back (C) | 67 in (170 cm) |

Bottom Bedder

The poultry bottom bedder is used to lay bedding for chickens, turkeys, and other fowl. The unit uses a rotating drum on the underside of the bucket to evenly lay down the bedding.

- Spreads wood shavings smooth and evenly

- Uses an agitator to break up sawdust for even flow

- Available in 5ft, 6ft, & 7ft bucket widths

| Model | Width | Capacity | Weight |

|---|---|---|---|

| M1500 | 5 ft | 1 yd | 850 lb. |

| M1600 | 5 ft | 1 1/3 yd | 950 lb. |

| M1700 | 7 ft | 2 1/4 yd | 1050 lb. |

Feed Caddy

- Guarantee consistent, uniform and repeatable feed distribution

- Save time and labour costs

- Prevent starve-outs and reduces mortality

- Increases feed coverage 600%

- Reduces feed waste

- Hitch to quad or small tractor

- Hand-pulled unit for small operations

- Feed chickens, turkeys, geese, ducks and game birds

- Adjust feed flow quickly and reliably for even feed amounts

- Prevent feed spills and sparse patches with feed flow linked to ground speed

| Model | Feed Weight | Length | Width | Height |

|---|---|---|---|---|

| Model 3630 | 440 lbs. | 4 ft. | 3 ft. 10 in. | 3 ft. |

| Model 4642 | 1,102 lbs. | 6 ft. 8 in. | 4 ft. 10 in. | 3 ft. 7 in. |

| Model 6044 | 2,204 lbs. | 7 ft. 8.5 in. | 4 ft. 10 in. | 4 ft. 4 in. |

Request A Quote

We look forward to building a relationship with you by providing you with practical solutions for your modern farming needs!